COMPANY

PROFILE

| Company Name | Hamana Engineering Co., Ltd. |

|---|---|

| President | Ken Goto |

| Established | April 30, 1974 |

| Capital | 46 million yen |

| Address | 1-10 Shin-Oguchi, Mitsuya-cho, Toyohashi City, Aichi Prefecture 441-3114, Japan |

| Business Activities | Design, manufacturing, sales, and services of automated transfer systems |

| Main Products |

|

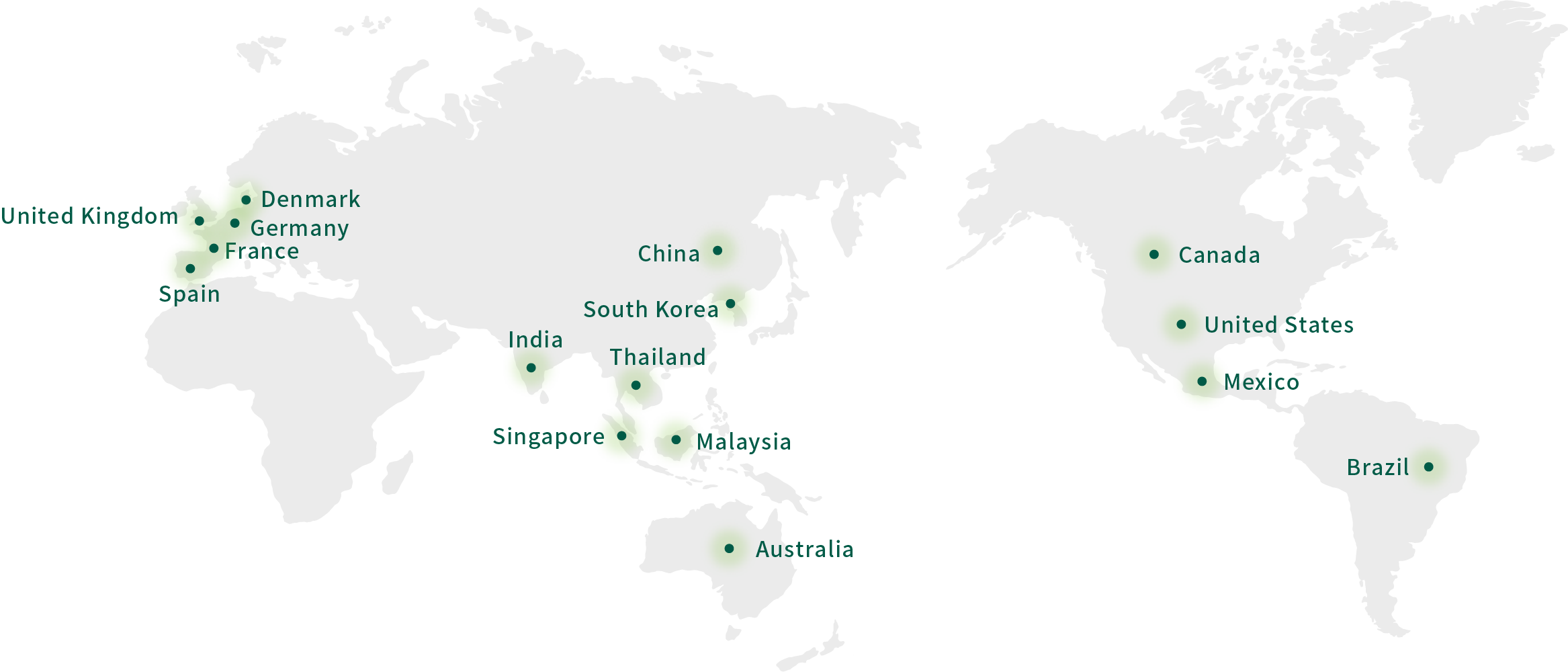

CLIENTS

- Machine manufacturers

- Enshu Limited

Okuma Corporation

Komatsu NTC Ltd.

Makino J Co., Ltd.

- Automobile manufacturers

-

Isuzu Motors Ltd.

Suzuki Motor Corporation

Subaru Corporation

Daihatsu Motor Co., Ltd.

Nissan Motor Corporation

Hino Motors, Ltd.

Honda Motor Co., Ltd.

Mitsubishi Motors

Mazda Motor Corporation General Motors Company (USA)

Ford Motor Company (USA)

Hyundai Motor Company (Korea)

Kia Corporation (Korea)

- Automotive parts manufacturers

- Ahresty Corporation

IJTT Co., Ltd.

Aichi Machine Industry Co. Ltd.

Kanada Kogyo Co., Ltd.

DENSO Corporation

Toyota Industries Corporation

Musashi Seimitsu Industry Co., Ltd.

Yamaha Motor Co., Ltd.

DMAX Ltd. (USA)

- Ship manufacturers

- Yamaha Motor Co., Ltd.

Tohatsu Marine Corporation

- Other manufacturers

- OSG Corporation

Kawasaki Heavy Industries Ltd.

Kubota Corporation

TMT Machinery Inc.

Mitsubishi Heavy Industries, Ltd.

Mitsubishi Electric Corporation

Mitsubishi Rayon Co., Ltd.

Hamana also has an extensive record of delivering to companies other than those listed above.

HISTORY

-

1970s

The company began operations.

- 1974:Established with capital of 3 million yen

- 1975:Developed and delivered an automatic transfer line with six connected grinding machines. Afterwards, automated/labor-saving transfer systems became the company’s main product.

- 1979:Increased capital to 8 million yen.

-

1980s

High speed gantry loaders released.

- 1981:Developed servo control with Toyohashi University of Technology.

- 1982:Increased capital to 23 million yen. Relocated our headquarters factory to Akemi-cho, Toyohashi City.

- 1984:Developed and delivered FMS lines for machine tool parts to machine manufacturers.

- 1986:Developed a high-speed gantry loader.

- 1987:Increased capital to 46 million yen.

-

1990s

Shipped 2,000 sets.

- 1990:Reached total shipments of 2,000 sets of automatic transfer equipment.

- 1992:Developed and delivered a gantry loader capable of transferring ultra-heavy objects (up to 500 kilograms).

- 1994:Developed and delivered a high-speed gantry loader (at a horizontal speed of 250 meters/minute).

- 1997:Reached total shipments of 2,500 sets of automatic transfer equipment.

- 1999:Developed and delivered a long-distance gantry loader. (with a total length of 150 meters)

-

2000s

Shipped 3,000 sets.

- 2000:Developed and delivered a high-speed gantry loader (at a horizontal speed of 300 meters/minute).

- 2001:Reached total shipments of 3,000 sets of automatic transport equipment.

- 2002:Developed and delivered a five-axis gantry loader for machining centers (29 cells).

- 2005:Achieved record-high sales, reached total shipments of 3,500 sets of automatic transfer equipment, and expanded administrative wing of headquarters.

- 2006:Completed a dedicated painting factory (equipped with cutting-edge ventilation system/capable of painting long pieces)

- 2009:Started joint research on optimal control methods with Toyohashi University of Technology.

- 2010:Converted all lighting in the administrative wing and factory to LED as an environmental initiative.

-

2010s

Shipped 4,500 sets.

- 2012:Reached total shipments of 4,000 sets of automatic transfer equipment.

- 2013:Grouped with SAN-EI Trading Co., Ltd.

- 2015:Exhibited at the Mechatronics Technology Japan 2015.

- 2017:Exhibited at the Mechatronics Technology Japan 2017.

- 2018:Developed and delivered IoT based traceability system lines (12 sets).

- 2019:Reached total shipments of 4,500 sets of automatic transfer equipment.

-

2020s

Headquarters relocated

- 2021:Exhibited at the Mechatronics Technology Japan 2021. Developed TARNAR.

- 2022:Exhibited at the Robot Technology Japan 2022.

- 2022:Started operations of the Toyokawa Factory.

- 2023:Exhibited at the Mechatronics Technology Japan 2023.

- 2023:Established factory in the Toyohashi City Mitsuya Industrial Park. Relocated our headquarters.

ACCESS

Location: 1-10 Shin-Oguchi, Mitsuya-cho, Toyohashi City, Aichi Prefecture 441-3114

5 minutes by car from Route 23 Hosoya Interchange / 3 minutes by car from Mitsuyacho Intersection on Route 1 / 7 minutes by car from Futagawa Station

GROUP COMPANIES